Common pitfalls to avoid when devising your plastics strategy

Not all plastics is bad (Part Two)

Plastic reduction and management is complex. On the one hand, plastic is a revolutionary material with myriad benefits that serve businesses and consumers. On the other hand, the ubiquity and affordability of plastic has led to overuse and mismanagement. When devising plastic mitigation strategies companies should consider three common missteps: substituting alternative materials for plastic (that lead to worse outcomes), inconsistent policy implementation and greenwashing.

Misstep 1: Ill conceived substitutions

Not all plastic is “bad”. In some instances plastic is a superior material in terms of lessening environmental impact. As a strong yet lightweight material, plastic can significantly reduce carbon emissions in packaging. It’s therefore crucial to consider the consequences of substituting alternate materials for plastic, particularly through the lens of local conditions. For example, polylactic acid (PLA) cups are bio-based and made from renewable materials but improper disposal can lead to contamination of recycled plastic waste streams – or simply additional landfill waste, in the absence of local composting facilities.

Case study

An airline was facing public pressure to reduce single-use plastic, including plastic cutlery, on board flights. The simple answer was to substitute different materials for the single-use plastic, such as heavier metal cutlery. The challenge, however, was that doing so would increase the overall plane loading, and hence carbon emissions. Additionally, the switch to washable items could increase the water footprint to an unacceptable level. The airline instead considered how best to manage unavoidable plastic waste generated on board. Energy was shifted to working with local waste management and recycling providers, to ensure that single-use plastic used on board flights was properly disposed of, and where possible, recycled.

Misstep 2: Inconsistent implementation

Beware the perils of inconsistent implementation of goals. For example, a hotel might enact a blanket ban on single-use plastic in its front of house operations but in reality the largest source of this plastic type likely stems from back of house operations, vis-a-vis plastic wrapping associated with delivery of food and products. The key to consistent implementation is 1) a thorough analysis of plastic use across the business, to better understand areas of greatest impact and 2) a solid internal communications plan to create employee buy-in and ownership.

What successful implementation looks like

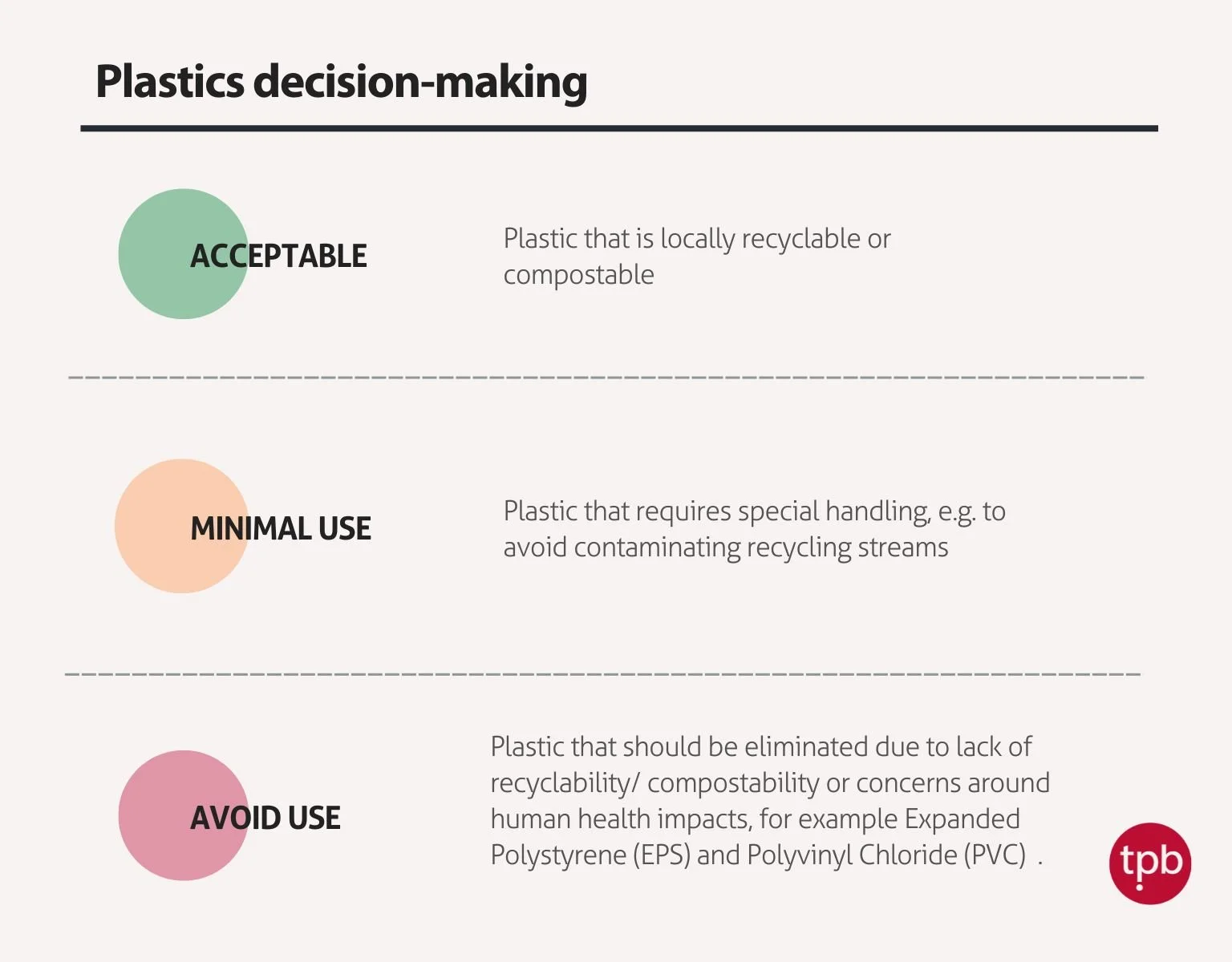

Changes to the status quo can be disruptive. When implementing new plastic management strategies, ensure that affected staff and suppliers understand what the goals are and the rationale underpinning them. Bring staff and suppliers into the process by giving them an opportunity to contribute ideas and voice concerns. By empowering the persons on the ground you will engender ownership, and potentially discover more effective strategies. To simplify decision making around plastic, so that staff feels confident acting without consulting management, TPB has created a decision tree that groups plastic into three categories :

Misstep 3: Greenwashing

A strong plastics management strategy should be accompanied by an external communications plan. Such a plan needs to be vetted for greenwashing and include double and and triple checking a company’s efforts before telegraphing them. For example, if your company switches from a fossil fuel-based plastic to plant-based plastic with the same polymer structure, it’s important to acknowledge that the material is still plastic. Compostables in general can be problematic, despite best intentions. If your company adopts compostable plastic materials but doesn’t ensure proper waste management of such they behave much like the worst single-use plastic offenders, leaving microplastics and nanoplastics in the environment for decades. Before touting the use of compostable plastic, make sure your company has an end-of-life plan in place for collection and proper disposal.

It’s important to recognize that complications will arise even in the most carefully constructed plastic management strategies. Avoiding the common missteps discussed above will help but miscalculations are inevitable. Transparency is critical when addressing errors. Communicate clearly and widely with stakeholders, including what went wrong, why and what the plan for remediation is.

Main contributor: Dr Merrin Pearse, The Purpose Business